Company Introduction

Zhuzhou Jintai Tungsten Carbide Co., Ltd., established in 2001, is located in the renowned tungsten carbide production base of China, Jingshan Industrial Park in Zhuzhou, Hunan. With an area of over 13,000 square meters, Zhuzhou Jintai Tungsten Carbide Co., Ltd. is a professional manufacturer specialized in the production, design, and sales of tungsten carbide cutting tools, engineering components, forming tools, wear-resistant parts, and related tungsten carbide saw materials. We serve as a beacon of cutting-edge technology and innovation.

Our products are at the forefront domestically, and we have obtained ISO9001, ISO14001, CE, GB/T20081 ROHS, SGS, and UL certifications. As a high-tech enterprise dedicated to the research, development, and manufacturing of tungsten carbide products, we have become trusted partners of leading institutions such as Central South University and Hunan University of Technology, collaborating on groundbreaking research projects. With meticulous attention to production and testing, our products have gained wide acclaim in more than 30 countries, establishing us as a global leader with an annual production capacity exceeding 500 tons of high-quality tungsten carbide blanks.

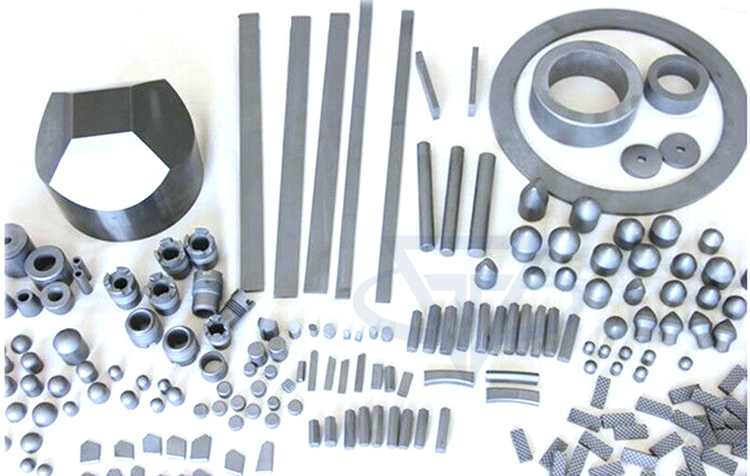

The core of our manufacturing capabilities lies in providing a wide range of products. From tungsten cobalt tungsten carbide cutting inserts to die materials, wear-resistant and anti-wear blanks, geological mining tools, woodworking saw blade tips, milling cutters, and drill rods – our catalog boasts over 100 carefully crafted varieties. Our tungsten carbide materials encompass over 30 different grades, including tungsten cobalt, tungsten cobalt titanium, and tungsten cobalt tantalum, possessing the power to revolutionize industries. We take pride in our ability to fulfill custom orders, skillfully producing non-standard tungsten carbide components based on your unique specifications. Furthermore, we excel in providing comprehensive tungsten carbide tooling solutions tailored to your machining needs.

Our steadfast commitment to innovation has resulted in over 20 patented products, exemplifying our dedication to pushing boundaries. From tungsten carbide fracturing safety hammerheads to fiber optic cutting blades, drainage cleaning wheels, tungsten steel alloy stone processing blades, and electronic stamping die materials, our inventions have received international recognition, proving their outstanding quality and performance. Under the trademark "Jintai," we have become synonymous with excellence and reliability, earning the trust and praise of customers both domestically and internationally.

Driven by the principles of "quality first" and "integrity management," we will strive to conduct pioneering research, implement rigorous management practices, and steadfastly commit ourselves to meeting the ever-changing demands of our customers. Our vision is to establish ourselves as a leading domestic brand in the industry, and we warmly welcome esteemed individuals from around the world to witness our unwavering pursuit of excellence.

Company Display

Our Team

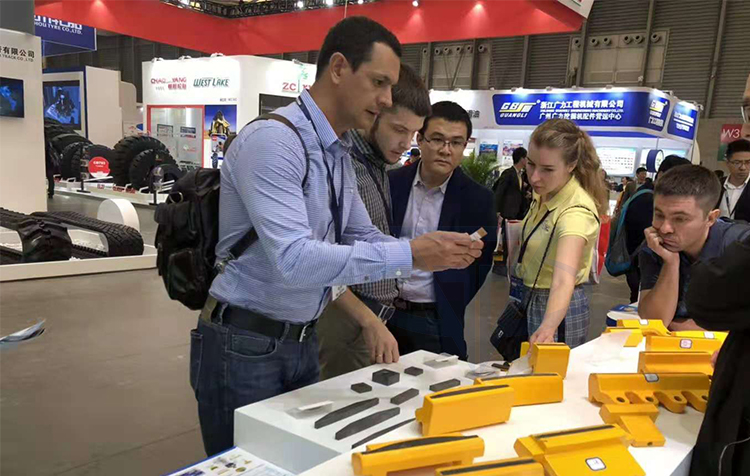

Our Customer

Certifications

Company History

-

2001

Established in 2001, Zhuzhou Jintai focuses on the manufacturing of hard alloy blades and enjoys a good reputation in the field.

-

2002

In 2002, the business expanded to include custom-made hard alloy wear parts.

-

2004

In 2004, it was awarded the title of a member unit of Zhuzhou Small and Medium-sized Import and Export Enterprises Association.

-

2005

On March 7, 2005, the Jintai brand trademark was successfully registered.

-

2005

Since 2005, it has been awarded the title of "Zhuzhou Municipal Contract-abiding and Creditworthy Unit" by the Zhuzhou Administration for Industry and Commerce for multiple consecutive years.

-

2006

In 2006, it actively developed overseas trade business.

-

2007

In 2007, it purchased new land and constructed a modern factory.

-

2010

In 2010, it became a quality supplier to China National Nuclear Corporation, providing them with hard alloy blades, molds, wear parts, as well as mining drill bits, saw blades, and other products.

-

2012

In 2012, it obtained the ISO9001 certification, marking the achievement of international standards in Zhuzhou Jintai's quality management system.

-

2015

On August 14, 2015, it officially became a member unit of the China Tungsten Industry Association.

-

2015

In 2015, to meet the demands of VIP customers, a new production line was established.

-

2017

In 2017, it reached a school-enterprise cooperation agreement with Hunan University of Technology, becoming a school-enterprise cooperation base.

-

2017

In 2017, the National Intellectual Property Administration granted Zhuzhou Jintai several utility model patent certificates, covering areas such as hard alloy knife sharpeners, stone polishing wheel structures, pipe cleaning scrapers, hard alloy cutting heads, end fittings for automotive safety hammers, and hard alloy sanding bars.

-

2018

In 2018, equipment and technology upgrades were carried out to enhance production efficiency and product quality.

-

2019

In 2019, Zhuzhou Jintai Hard Alloy Co., Ltd. was awarded the "High-Tech Enterprise Certificate" by the Department of Science and Technology of Hunan Province, the Department of Finance of Hunan Province, and the State Taxation Administration.

-

2022

In 2022, a new tungsten carbide plant was built to meet capacity requirements.