Description

Carbide saw blades are typically used on saws such as circular hand saws,miter saws and fixed table saws.Small pieces of carbide metal are secured to a round metal blade. A high temperature resistant epoxy is used to hold the carbide teeth in place. Carbide teeth have the advantage of being very hard, so they can maintain a sharp edge for a very long time

1. Grades: YG6X,YG6,YG8,YG8X,JX10,JX15,JX35,JX40 etc

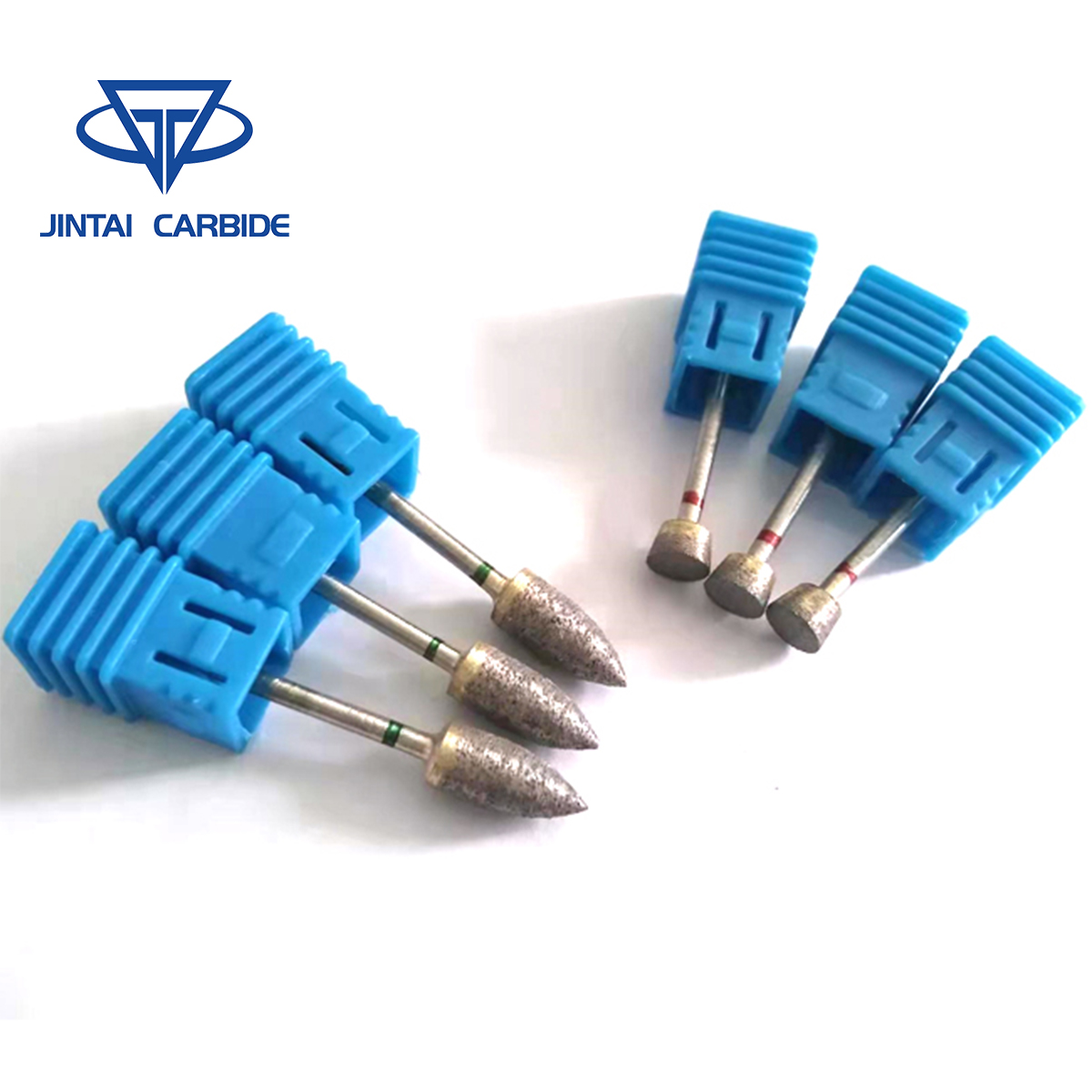

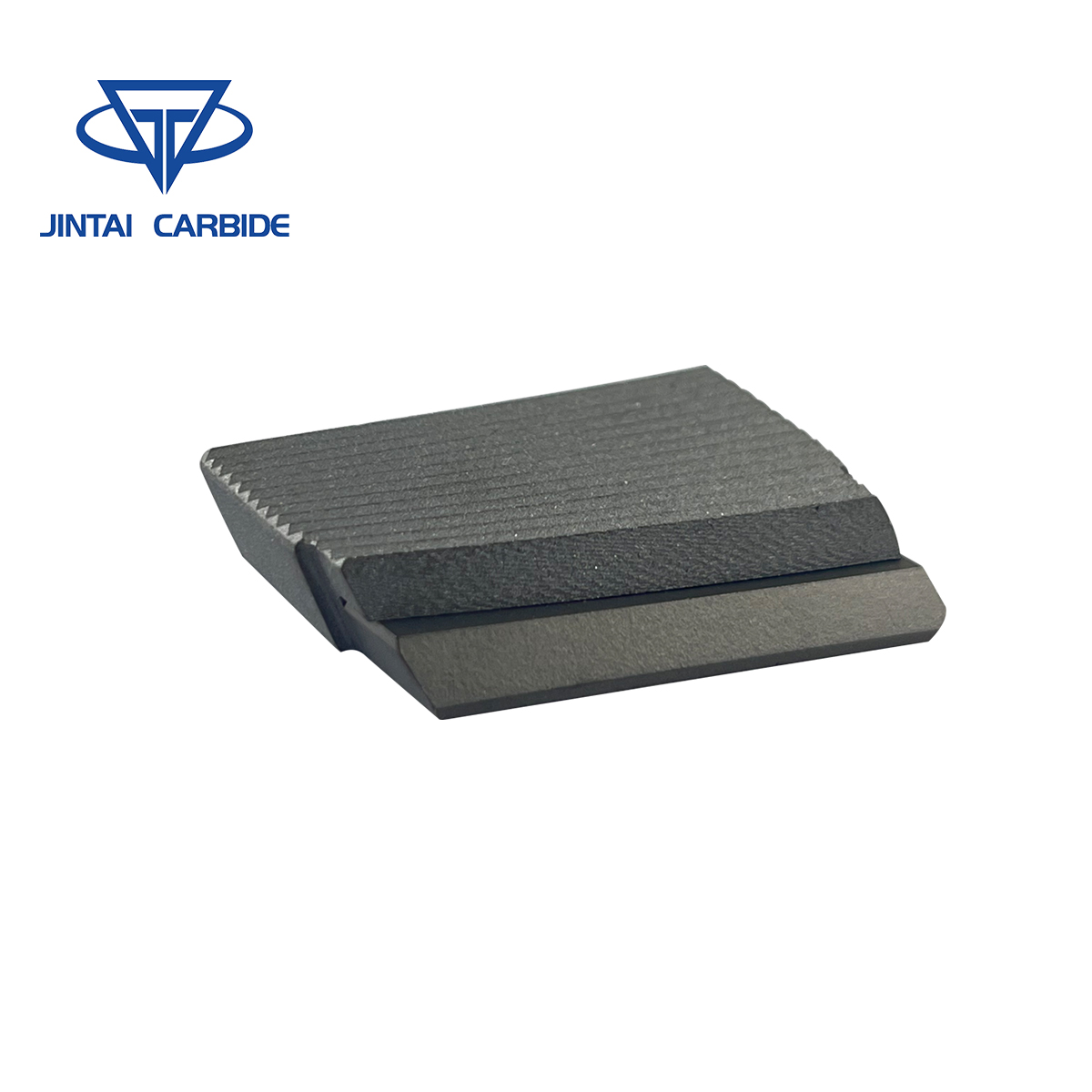

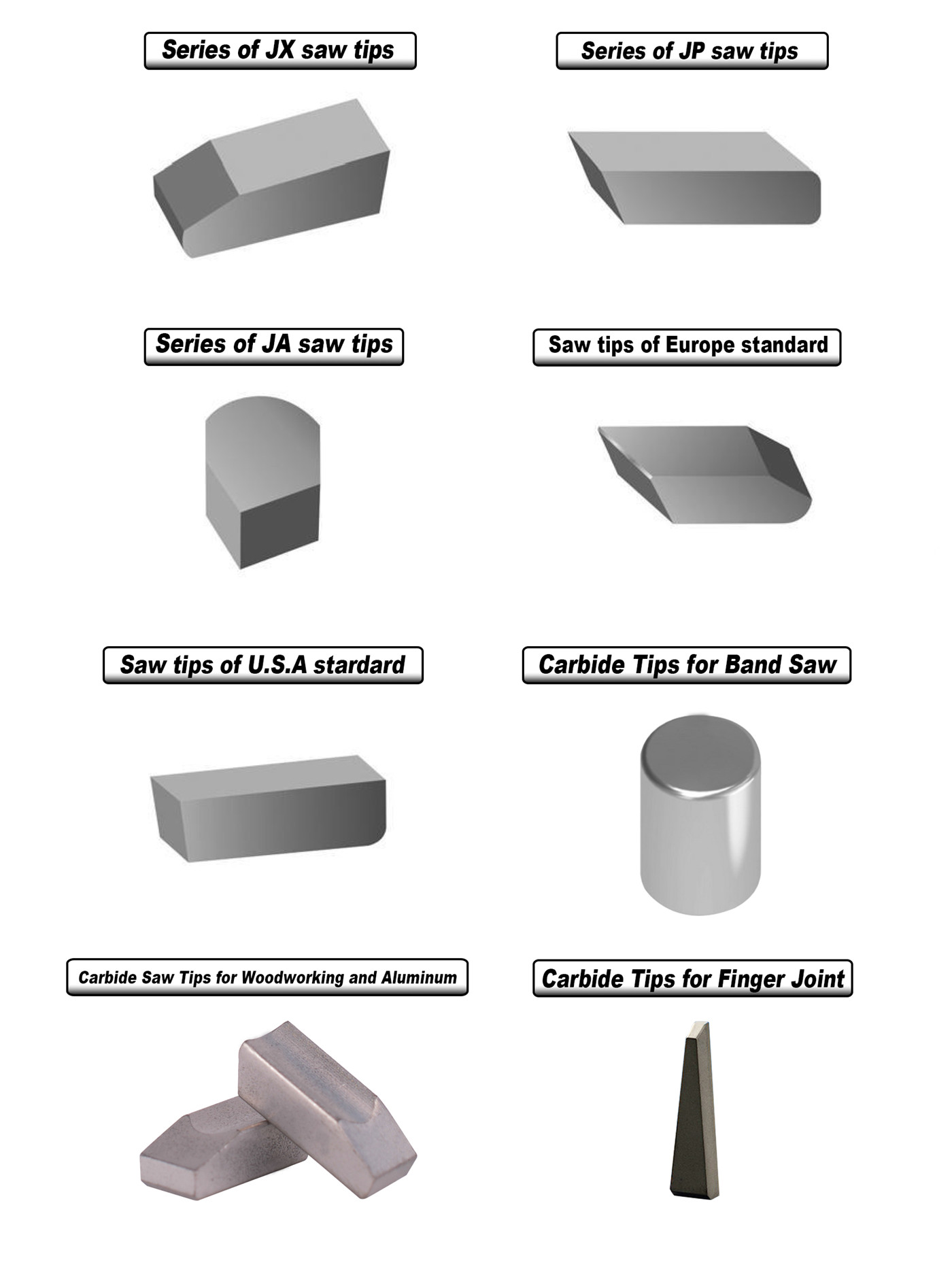

2. the saw tips include JX series,JP series,JA series, USA Standard and European Standard etc.

3. All saw tips are HIP-Sintered, to make sure high quality, with automatic pressing to make sure accurate size, tumble and nickel covered to make sure good brazing performance.

4. Our brand has gain reputation from clients in Europe, USA, Asia, etc.

5. Our grades cover all ISO range, suitable to cut grass, hard wood, recycle wood, metal, plastic, PVC, MDF, Melamine board, plywood, etc.

High toughness and breakage resistance, our saw blades are designed for stability and reliability. No matter what material you're cutting, our blades will always deliver great performance. Whether it's wood, metal, or even plastic, our saw blades glide effortlessly to give you perfect cuts every time.

These inserts feature high toughness, fracture resistance and a HIP sintering process that guarantees stability, reliability and a long-lasting cutting edge. Our state-of-the-art automated manufacturing ensures consistent quality and greater efficiency, while our support for a wide range of specifications and customization options meet all your different cutting needs.

Unlock the cutting-edge potential of Tungsten Carbide Saw Tips! As a cross-border e-commerce enthusiast, you've come to the right place for premium Tungsten Carbide Saw Tips that excel in various cutting applications, ensuring superior performance and extended lifespan.

Expertly engineered with precision, our Tungsten Carbide Saw Tips boast exceptional hardness and wear resistance, making them the ultimate choice for sawing tasks in woodworking, metalworking, and more. Count on these tips to deliver precise cuts and unparalleled durability, revolutionizing your cutting processes.

Not just tough, our Tungsten Carbide Saw Tips exhibit exceptional heat resistance, ensuring consistent performance even in high-temperature environments. Experience their ability to maintain sharpness and reliability, enabling you to optimize productivity and minimize downtime.

At JINTAI, we take immense pride in delivering products that meet the highest quality standards. Each Tungsten Carbide Saw Tip undergoes stringent testing, ensuring consistency and excellence, empowering you to achieve remarkable results in your cutting projects.

Embrace efficiency and cost-effectiveness with our premium Tungsten Carbide Saw Tips, and gain a competitive edge in your industry. Partner with us today to experience the unparalleled performance these tips bring to your cutting operations.

Choose JINTAI for reliable, high-performance Tungsten Carbide Saw Tips, and witness their true potential in elevating your business to new heights. Place your order now and harness the power of our top-tier sawing solutions.

Grade List

| Grade | ISO Code | Physical Mechanical Properties (≥) | Application | ||

| Density g/cm3 |

Hardness(HRA) | T.R.S N/mm2 |

|||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Suitable for precision machining of cast iron and non-ferrous metals. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Suitable for precision machining and semi-finishing of cast iron and non-ferrous metals, as well as for processing of manganese steel and quenched steel. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Suitable for semi-finishing and rough machining of cast iron and light alloys, and can also be used for rough machining of cast iron and low alloy steel. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Suitable for inlaying rotary impact rock drilling and rotary impact rock drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Suitable for inlaying chisel-shaped or conical teeth bits for heavy-duty rock drilling machines to tackle hard rock formations. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Suitable for tensile testing of steel bars and steel pipes under high compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Suitable for making stamping dies. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Suitable for making cold stamping and cold pressing dies for industries such as standard parts, bearings, tools, etc. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Suitable for precision machining and semi-finishing of stainless steel and general alloy steel. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Suitable for semi-finishing of stainless steel and low alloy steel. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Suitable for precision machining of iron-based, nickel-based high-temperature alloys, and high-strength steel. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Suitable for heavy-duty cutting of steel and cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Suitable for precision machining and semi-finishing of steel and cast iron. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Suitable for precision machining and semi-finishing of steel and cast iron, with moderate feed rate. YS25 is specially designed for milling operations on steel and cast iron. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Suitable for heavy-duty cutting tools, providing excellent results in rough turning of castings and various steel forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Suitable for inlaying rotary impact rock drilling bits and drilling in hard and relatively hard rock formations. |

Order Process

Production Process

Packaging