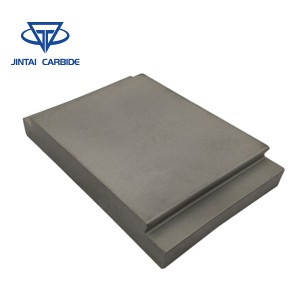

Description

Grade diversity, comprehensive size range, allowing free selection of product grades and sizes (YG6/YG6X/YG8/YG8X/YG15/YG20C/YG25...).

Excellent density, uniform dimensions, good flatness, high hardness, super wear resistance, corrosion resistance, no pores, no bubbles, smooth surface with no cracks, distinct edges and corners, good perpendicularity. Bending strength ranges from 90 to 150MPA, stable chemical properties, high thermal conductivity, low thermal expansion coefficient, and excellent compressive strength.

Application Range: Mechanical industry, aerospace, automotive industry, petrochemicals, transportation construction, electronic products, oil exploration, watchmaking, automotive manufacturing, shipbuilding, aircraft manufacturing, papermaking, mold production, mechanical equipment parts, etc.

Our tungsten carbide plates are used in a variety of industries and applications requiring strong and durable components. From mining and construction to manufacturing and metalworking, these plates improve the performance and lifespan of equipment. Whether used for cutting, drilling, crushing, or any other application requiring wear resistance and high precision, our plates provide unrivaled performance and reliability.

With their high wear resistance, extremely hard material, high precision dimensional control and exceptional toughness, these plates can extend the life of your equipment, ensuring stability and unbreakable performance.

Discover the excellence of Tungsten Carbide Plates for your cross-border e-commerce ventures. Look no further as our premium Tungsten Carbide Plates offer the perfect solution for diverse industrial applications, ensuring exceptional performance and long-lasting durability.

Meticulously crafted with precision and expertise, our Tungsten Carbide Plates stand out with remarkable hardness and wear resistance, making them the ultimate choice for cutting, shearing, and various machining tasks. From metalworking to mining, these plates deliver impeccable results and reliability, making your projects a success.

Beyond their outstanding toughness, our Tungsten Carbide Plates exhibit exceptional heat resistance, guaranteeing consistent performance even under the most demanding high-temperature conditions. Count on them to retain their sharpness and maximize productivity while minimizing downtime.

At JINTAI, we take immense pride in maintaining the highest quality standards. Each Tungsten Carbide Plate undergoes rigorous testing, ensuring uniformity and top-tier performance, empowering you to excel in your most challenging endeavors.

Elevate your industrial processes with our premium Tungsten Carbide Plates and witness a significant boost in efficiency and cost-effectiveness. Partner with us today and gain a competitive edge in your industry.

Select JINTAI for reliable, high-performance Tungsten Carbide Plates, and unleash their true potential in propelling your business to new heights. Place your order now to experience the superior quality and endurance our plates have to offer.

Grade List

| Grade | ISO Code | Physical Mechanical Properties (≥) | Application | ||

| Density g/cm3 |

Hardness(HRA) | T.R.S N/mm2 |

|||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Suitable for precision machining of cast iron and non-ferrous metals. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Suitable for precision machining and semi-finishing of cast iron and non-ferrous metals, as well as for processing of manganese steel and quenched steel. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Suitable for semi-finishing and rough machining of cast iron and light alloys, and can also be used for rough machining of cast iron and low alloy steel. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Suitable for inlaying rotary impact rock drilling and rotary impact rock drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Suitable for inlaying chisel-shaped or conical teeth bits for heavy-duty rock drilling machines to tackle hard rock formations. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Suitable for tensile testing of steel bars and steel pipes under high compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Suitable for making stamping dies. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Suitable for making cold stamping and cold pressing dies for industries such as standard parts, bearings, tools, etc. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Suitable for precision machining and semi-finishing of stainless steel and general alloy steel. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Suitable for semi-finishing of stainless steel and low alloy steel. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Suitable for precision machining of iron-based, nickel-based high-temperature alloys, and high-strength steel. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Suitable for heavy-duty cutting of steel and cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Suitable for precision machining and semi-finishing of steel and cast iron. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Suitable for precision machining and semi-finishing of steel and cast iron, with moderate feed rate. YS25 is specially designed for milling operations on steel and cast iron. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Suitable for heavy-duty cutting tools, providing excellent results in rough turning of castings and various steel forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Suitable for inlaying rotary impact rock drilling bits and drilling in hard and relatively hard rock formations. |

Order Process

Production Process

Packaging