Description

Face Milling Cutter For Aluminum Ingot

Product Overview:

The aluminum ingot face milling cutter is designed for surface milling before the hot rolling

process of aluminum ingots.The aluminum material face milling cutter series includes rough

milling cutters,precision milling cutters,and coated milling cutters.The rough milling cutter

is used for the bulk milling of rough blanks.The precision milling cutter is used to improve the

surface smoothness of aluminum ingots.The coated milling cutter enhances the wear resistance and lifespan of the blades.

Product Features:

1、The milling edge is sharp,resulting in a smooth surface on the milled aluminum ingot,with good

processing stability.

2、The blade has high density and stability,offering excellent impact resistance and wear resistance. 3、The blade surface has good smoothness,ensuring a non-adhesive and non-burning milling process.

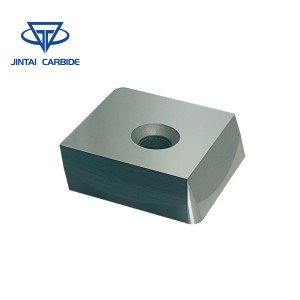

Rough Milling Cutter:

| Order Code | Dimension(mm | ||||

| L | R | d | S | s1 | |

| JT6206-L | 37.4 | 3 | 7 | 8 | 2 |

| Order Code | Dimension(mm) | ||||||

| L | R | S | S1 | S2 | d | d1 | |

| JT6206-M | 30 | 3 | 8 | 2.4 | 0.65 | 8.2 | 7.2 |

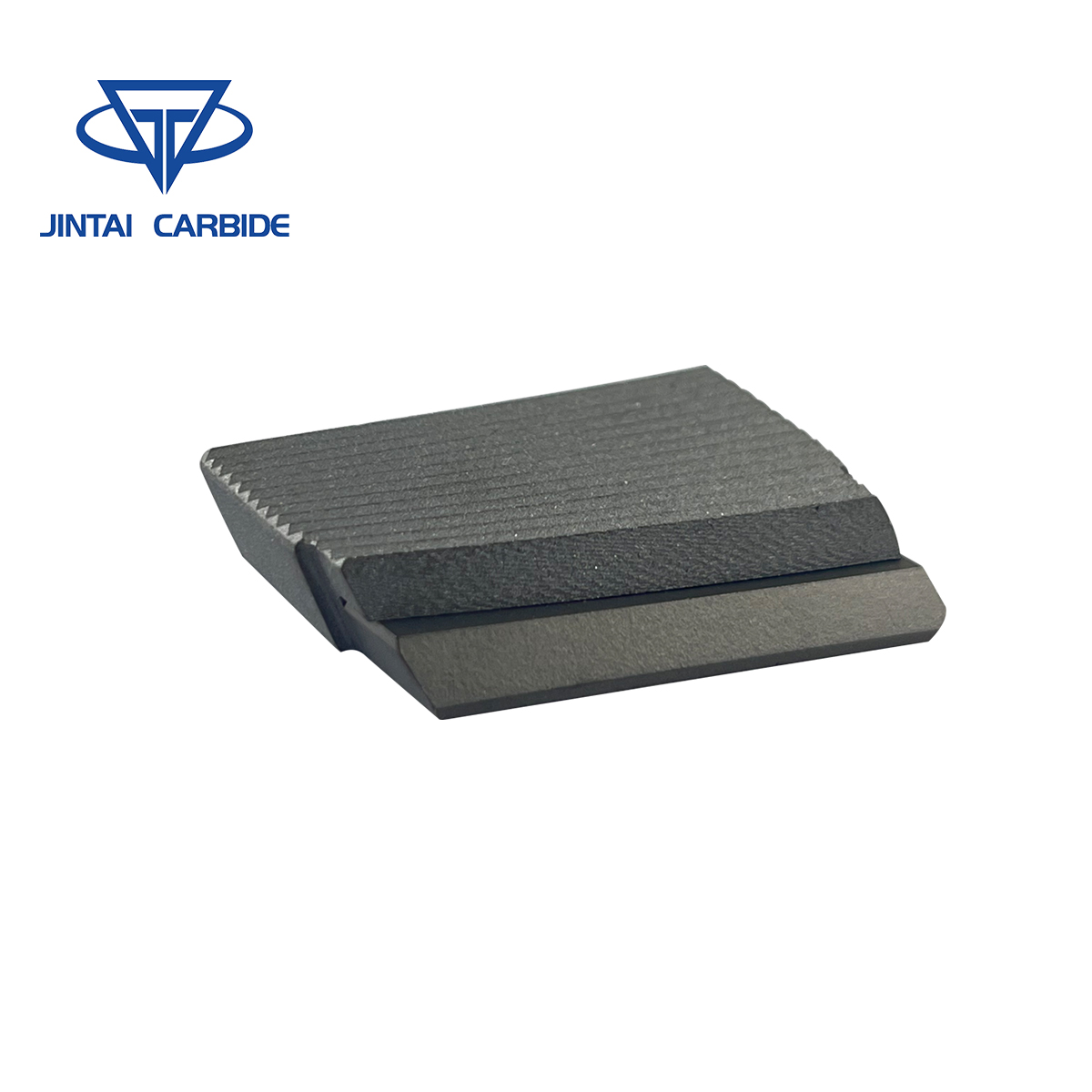

Finish Milling Cutter:

| Order Code | Dimension(mm) | ||||||

| L | L1 | R | R1 | S | S1 | d | |

| JT6027 | 37.4 | 37.08 | 3 | 730 | 8 | 2 | 7.4 |

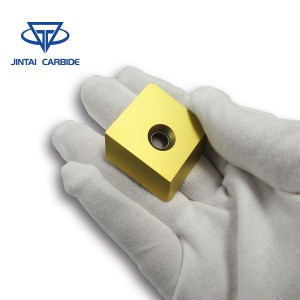

Coated Milling Cutter:

Grade List

| Grade | ISO Code | Physical Mechanical Properties (≥) | Application | ||

| Density g/cm3 |

Hardness(HRA) | T.R.S N/mm2 |

|||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Suitable for precision machining of cast iron and non-ferrous metals. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Suitable for precision machining and semi-finishing of cast iron and non-ferrous metals, as well as for processing of manganese steel and quenched steel. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Suitable for semi-finishing and rough machining of cast iron and light alloys, and can also be used for rough machining of cast iron and low alloy steel. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Suitable for inlaying rotary impact rock drilling and rotary impact rock drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Suitable for inlaying chisel-shaped or conical teeth bits for heavy-duty rock drilling machines to tackle hard rock formations. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Suitable for tensile testing of steel bars and steel pipes under high compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Suitable for making stamping dies. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Suitable for making cold stamping and cold pressing dies for industries such as standard parts, bearings, tools, etc. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Suitable for precision machining and semi-finishing of stainless steel and general alloy steel. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Suitable for semi-finishing of stainless steel and low alloy steel. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Suitable for precision machining of iron-based, nickel-based high-temperature alloys, and high-strength steel. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Suitable for heavy-duty cutting of steel and cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Suitable for precision machining and semi-finishing of steel and cast iron. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Suitable for precision machining and semi-finishing of steel and cast iron, with moderate feed rate. YS25 is specially designed for milling operations on steel and cast iron. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Suitable for heavy-duty cutting tools, providing excellent results in rough turning of castings and various steel forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Suitable for inlaying rotary impact rock drilling bits and drilling in hard and relatively hard rock formations. |

Order Process

Production Process

Packaging